Capabilities Overview

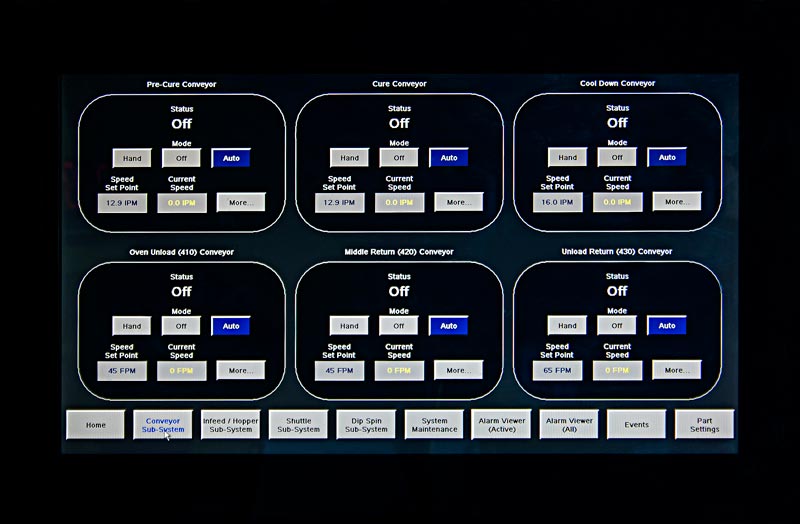

DIFCO’s automatic lines are operated by Programmable Logic Controllers (PLC) with touch screen interfaces. The automatic lines were built by DIFCO’s Engineering Team to provide increased efficiency and greater flexibility. Highly Detailed Production reports are printed daily. Computer analysis calculates process line productivity, efficiency and provides the status of each plating line.

Metal Finishing Capabilities Include:

5 Automatic Computer Controlled Metal Plating Lines

- Racks up to 144″ x 60″ x 24″ (12′ x 5′ x 2′)

- Barrels up to 600 pounds

4 Manual Controlled Plating Lines

- Rack and Barrel Capabilities

Atomic Absorption Spectrophotometer - AA

- Determine very small concentrations of various metal compounds in plating bath chemistry, and waste water treatment systems

- X-Ray Fluorescence

- Used to accurately check plating thickness

Full Chemical Lab

- Chemistry is kept at optimal concentrations

- Lab analysis software tracking trends, control points, and bath chemistry history

Shop Management System

- Work instructions specific to our customer’s part and process

- Detailed history of part specific information

THE DIFCO DIFFERENCE

We Make Your Parts Look Better, Work Better and Last Longer

Call 770-934-7100

Get A Quote